20~60HRC Plastic Injection Mold of PP Component for Medical Products

Package Size 45.00cm * 66.00cm * 42.00cm Package Gross Weight 720.000kg Howe mold supply the highest-quality Plastic pro

Basic Info.

| Model NO. | HW-959 |

| Plastic Material | TPE |

| Process Combination Type | Single-Process Mode |

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware |

| Runner | Hot Runner |

| Design Software | AutoCAD |

| Installation | Fixed |

| Certification | ISO |

| Standard | PUNCH |

| Customized | Customized |

| Product Material | ABS,TPE,TPV,Tpo,etc |

| Cavity Material | 738, 738h, 718, 718h, ,etc |

| Mold Cavity | Single, Multi, Family |

| Lead Time of First Samples | Around 4~7weeks |

| Weekly Report | We Will Update The Mold Schedule Every Week |

| Mold Life | 300,000-500,000 Shots |

| Ejection System | Stripper Plate,Lifter,Push Bar,Ejection Pin etc |

| Gate Type | Side Gate,Sub Gate,Pin Point Gate,Edge Gate etc |

| Product Name | Plastic Injection Molds |

| Manufacture Type | Injection Mold, Surface Treatment Available |

| Transport Package | Hard Carton, or Customized |

| Specification | According to your drawing |

| Trademark | OEM |

| Origin | Guangdong, China |

| HS Code | 8522901000 |

| Production Capacity | 250sets/Year |

Packaging & Delivery

Package Size 45.00cm * 66.00cm * 42.00cm Package Gross Weight 720.000kgProduct Description

Howe mold supply the highest-quality Plastic products and services that bring value to our customers. Be creative and innovative as we improve and expand our product offerings. Surpass today's achievements tomorrow to be truly excellent.

Product Description

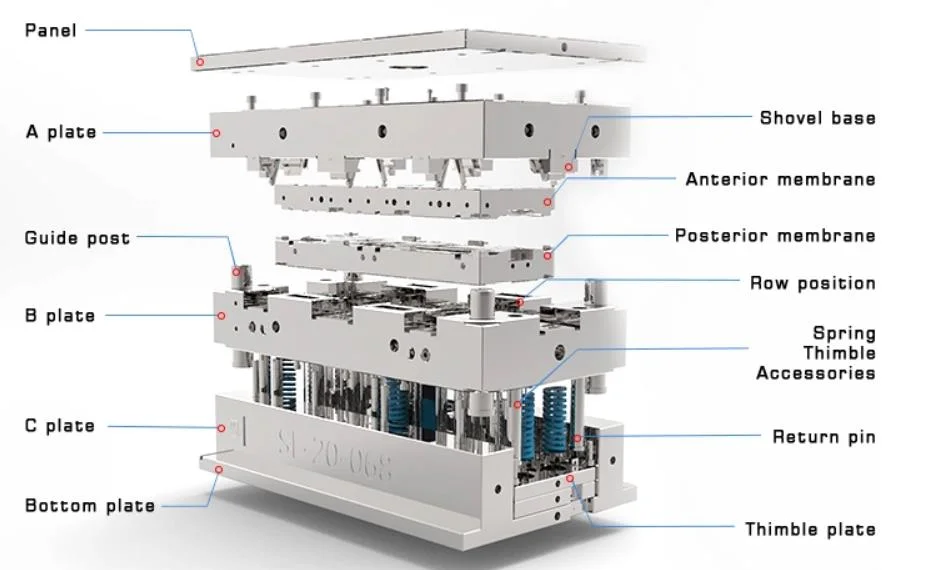

| Mould type | Plastic injection mould |

| Mould material | 45#, 50#, P20, 738, 738H, 718, 718H, NAK80, 2316, 2316A, S136 etc |

| Product material | ABS,PA6,PA66,PP,PC,TPU,POM,PBT,PVC,TPE,TPV,TPO,TPR,EVA,LDPE etc. |

| Runner system | Cold runner or hot runner |

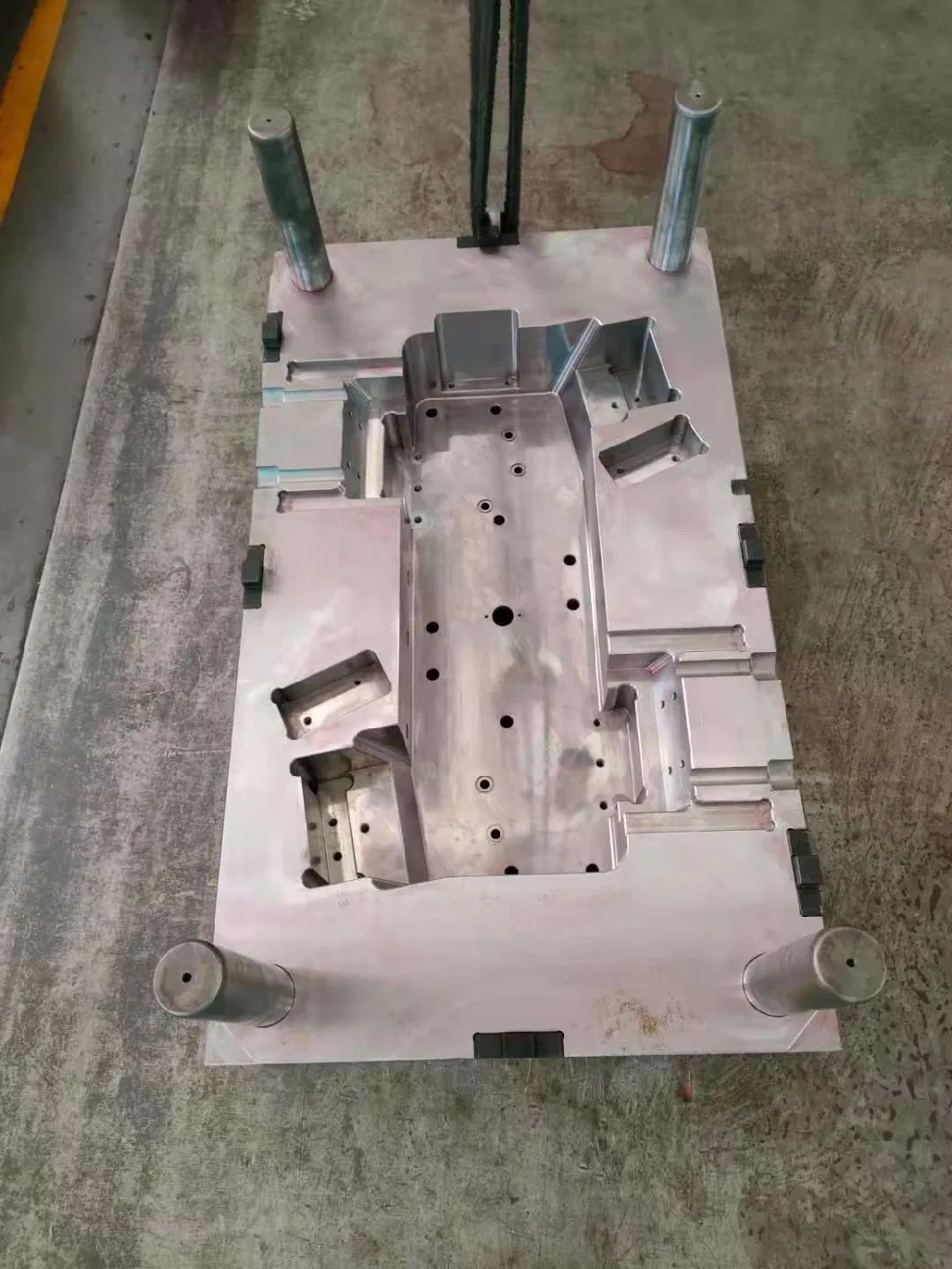

| Mould precision | ±0.01mm. |

| Mould machine center | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes etc. |

| Mould Base type | LKM, FUTA, HASCO, DME, TSMP, Or as per customer's requirement. |

| Steel hardness | 20-60HRC |

| R&D | 1. Drawing design and making for products and mold;2. Mold drawing revising;3. Production time and quality control in each machining process. |

| Mould lifetime | Commonly used:1. 300,000-500,000 shots for 1 year under normal use procedure for pre-hardness steel material.2. 500,000 shots for 1 year under normal use procedure for heat treatment steel material. |

| Port | SHEN ZHEN |

| Manufacture type | Injection mold, surface treatment available |

| Delivery | By DHL/FedEx/UPS/TNT, or by sea, depends on your time. |

| Supply ability | 30 sets per month |

Company Profile

Howe Precision Mold Co. is a qualified engineering and manufacturing company that designs and makes production tools of high-quality injection mold and die-cast mold for plastics molding and metal casting in wide ranges of automotive, household appliances, consumer goods, etc., with an engineering team over 11 average years of experience. Established in Dongguan City China, by the general manager Mr. Shawn Lee with the technical backgrounds.Committed to providing one-stop services from prototyping through toolings to high-volume product production with competitive price and short lead time based on advanced technologies, scientific management and continuous improvement.

Quality Control

OEM&ODM products as following:

Mould Trade Process

Quote: According to sample, drawing and specific requirement.↓Discussion: Mold material, cavity number, price, runner, payment, etc.↓ S/C Signature: Approval for all the items↓Advance Pay: 40% by T/T↓Product Design Checking: We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report↓Mold Tooling: We start to make mold after mold design confirmed↓Mold Processing: Send report to customer once each week↓Mold Testing: Send trial samples and try-out report to customer for confirmation.↓Pay :30% by T/T on trial samples↓ Mold Modification: According to customer's feedback↓ Balance settlement: 30% by T/T after the customer approved the trial sample and mould quality.↓ Delivery: Delivery by sea or air. The forwarder can be designated by your side.

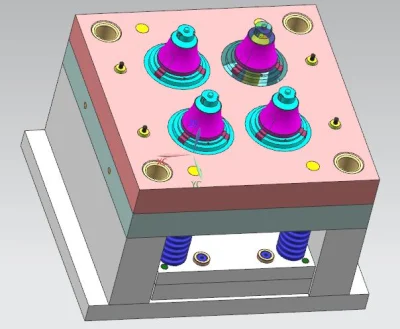

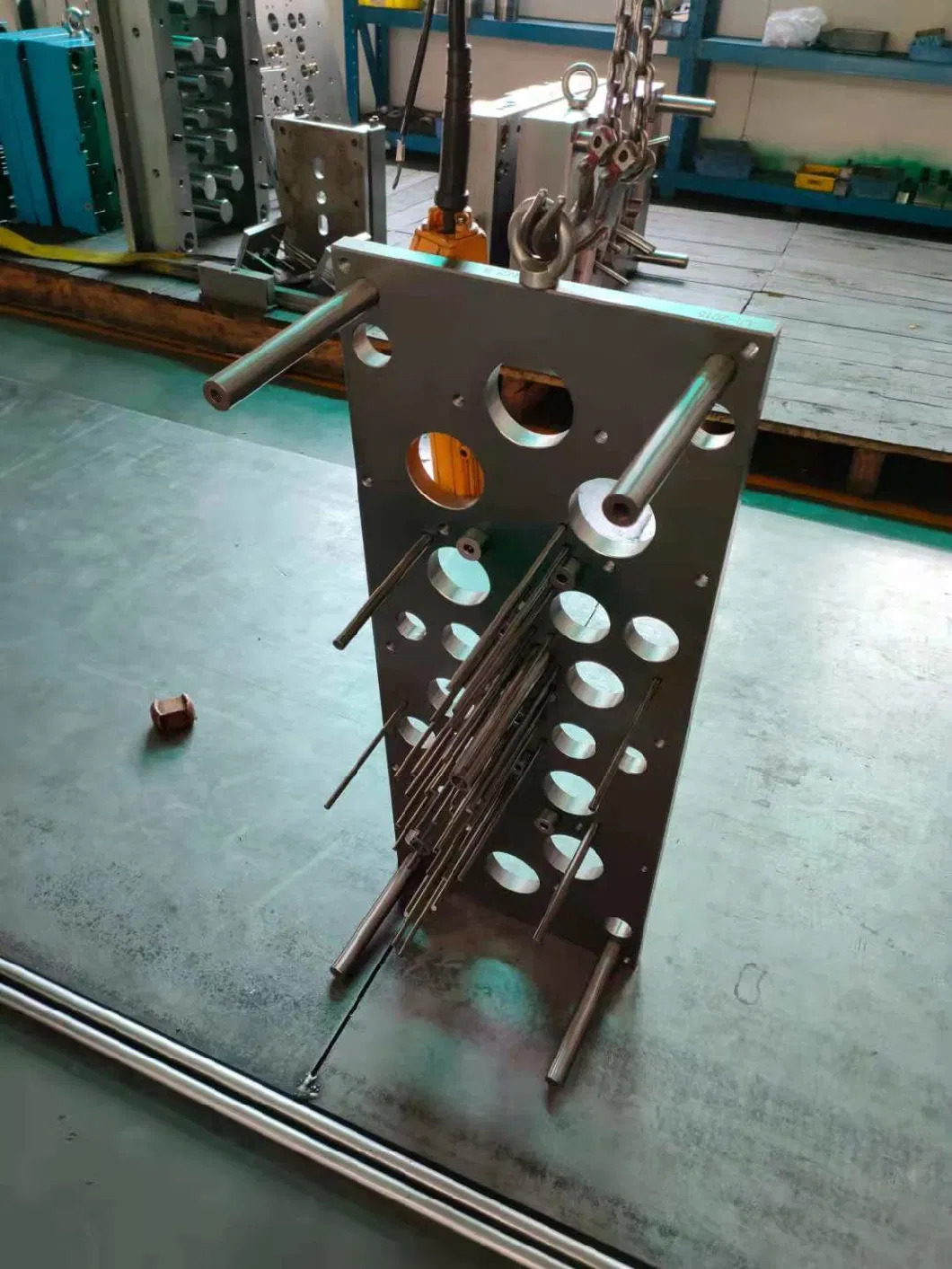

Glance at Molds

Glance at Plastic products

Business Cooperation

Package and Shipment

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.Q. I have an idea for a new product, but not sure if it can be manufactured. Can you help?A. Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.Q. My products have already been developed on CAD. Can you use the drawings?A. Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used to generate quotes, models and mould tools - this can save time and money in producing your parts.Q. Can I test my idea/product before committing to mould tool manufacture?A. Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.Q. What shall we do if we do not have drawings?A. Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.Q. What type of mould tool do I need?A. Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you

Q: How long is your delivery time?

A: Generally 5-7 days for plastic products.25 days around to make a simple molds, complicated ones can be 30~50 days. We use our company DHL, TNT, UPS account to ensure the fast product delivery time

Q: How many times try out?

A: 3 times and every time 2 sets sample with free delivery via DHL

Q: What is your terms of payment ?

A: Paypal, T/T.

Welcome your inquires and emails. All inquires and emails will be replied within 24 hours.Custom Plastic Parts Injection Molding Service BACK TO HOMEPAGE FOR MORE PRODUCTS!

Send to us