Automotive Engine Injection Water Tank Mould

Basic Info.

| Design Software | UG |

| Installation | Fixed |

| Customized | Customized |

| Mould Life | 500,000 Shots |

| Cavity | 1+1 |

| Mold Material | 718h |

| Lead Time | 70 Days |

| Transport Package | Wooden Canse |

| HS Code | 8480719090 |

| Production Capacity | 30 Set/Per Quarter |

Product Description

Product Description

| Mould Name | Automotive Engine Injection Water Tank Mould |

| Material | P20 / 718 / 2738 /H13 / S136 /NAK80 |

| Material | HRC28-HRC60 |

| Material Treatment | Quenching / Nitrided / Heat |

| Mold Surface | Texture / Mirror polish / Customizable |

| Mold Base | DME / LKM / HASCO / LOCAL |

| Products Material | PP / PE / PA / PS / PC / ABS / TPE / PET / PMMA |

| Delivery Time | Less than 45 days after mold design confirmed |

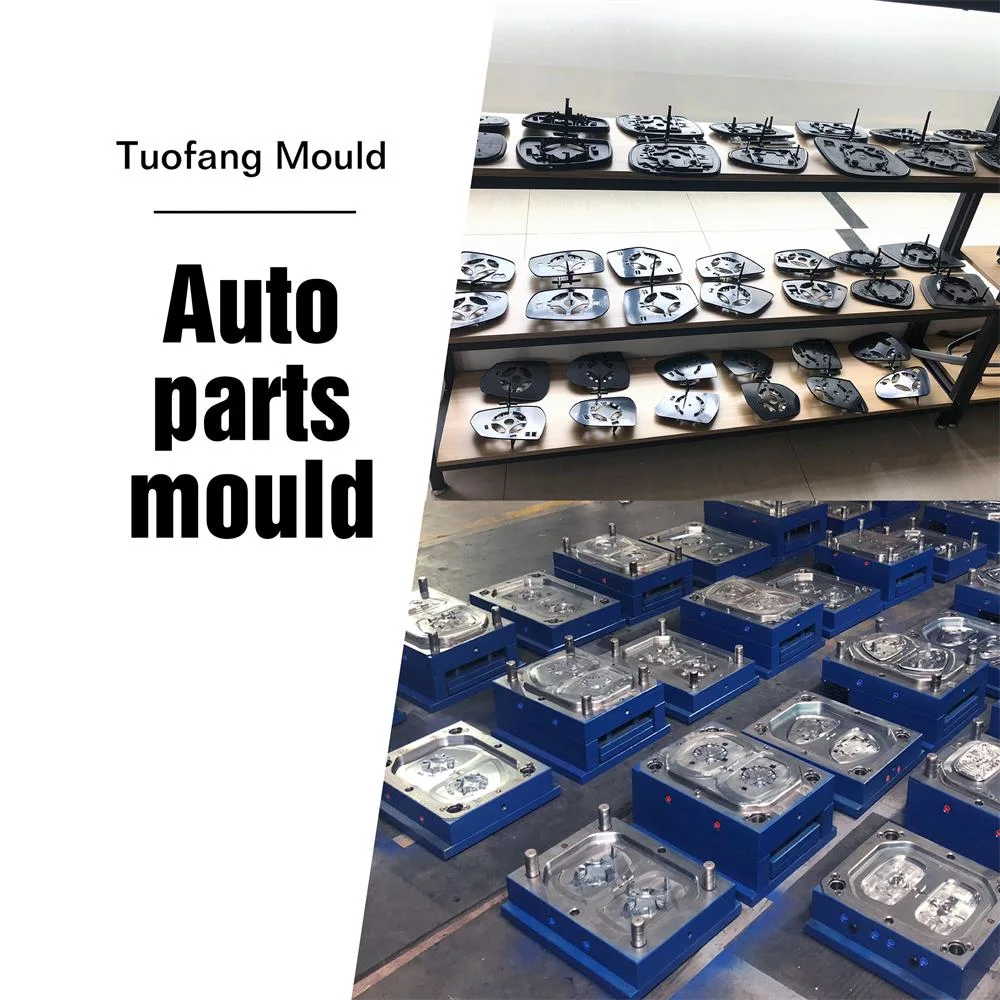

We are professional in making kinds of auto parts mould. Such as car radiator water tank mould, fan and fan shroud mould, auto interior part mould, grille mould, ,fender mould, car light mould, car rear view mirror etc.

Manufacturing Flow of mould

| 1.Sample/Drawing | We need your detail require clearly. |

| 2.Negotiation | Material,cavity,price,delivery time,payment term ,etc. |

| 3.Place order | According the confirmed design or samples |

| 4.Mould design | We will communicate&exchange the opinion with you during making drawing. |

| 5.Tooling mould | After customer approve the mould design will start making mould. |

| 6.Mould process | Provide photos for customer show them tooling process. |

| 7.Sample confirm | Send you sample for confoirm it ,if not satisfied by customer. we modify mould. |

| 8.Delivery mould | Delivery mould after customer approve sample and arrange shipment |

Packaging & Shipping

1.the surface of core and cavity will be covered by antirust.2.the mould surface will be covered by butter.3the mould will be packed by plastic membrane. 4.the mould will be put into wooden case. 5.some other spare parts and all date sheet(2D/3D drawing and revised drawing)will be prepare the some wear parts, like spring, ejector pins, cooling connector, eyeblot.pack with the mouldWe will prepare the some wear parts, like spring, ejector pins, cooling connector, eyeblot.pack with the mould

Company Profile

Our company has set its strategic objective which is "high standard, high precision, high efficiency" by taking quality as life. Based on the working-style of "Honesty and Practicality, Persevering Unremittingly, Teamwork Spirit, Achieving Greatness", our company would like to sincerely invite the global prospective customers to pay a visit and have a good cooperation for a splendid future together.Design capacity

Advanced software programs such as UG-NX, CAD are applied to design moulds, and MOLD FLOW to evaluate pre-design front sprue, cooling system, parts deformation, meldline and to trouble-shoot post-design product defects.Production capacity

We have CNC, engrave, line cutting, EDM and drill machine, and cooperate with outside processing center, the factory has a capacity of designing and producing 150-200 sets of mould annually.

After Sales Service

Pre-sale service:The good sale person for professional and promptly communicationIn-sale service: Our designer teams will support customer R&D,make the product and mould design as per customer request, do the modification and give the professional suggestion for improve the product. Update the mould process to customerAfter-sale service: Suggest the mould maintance, If the mould have quality problem during our guarantee period, will freely supply the wear part for replace the broken piece and technique support; also if you have any issue in using our moulds, we provide the professional suggestions and helps

Tuofang Customer

FAQ

Q. Are you manufacture?

A: Yes, we are plastic injection mould manufactureQ. I have no 3D drawing, how should I start the new project?

A: We very welcome you give us the samples, we will help you finish the 3D drawing design

Q: I have an idea for a new product, but don't know if it can be manufactured. Can you help?

A: Yes! We are always happy to work with customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs

Q: How to make sure the quality before the shipment?

A: will send the mould tooling schedule, mould pictures and processing report to buyer each 10 days. After mould fiished we will do the testing to make sure the mould is work well, we will send all testing picture and video to customer

Q: How to send sample?

A:The quotation we offer to you including the cost of sample delivery 1-2 times. We send sample by DHL, UPS, EMS ,FEDEX or TNT.