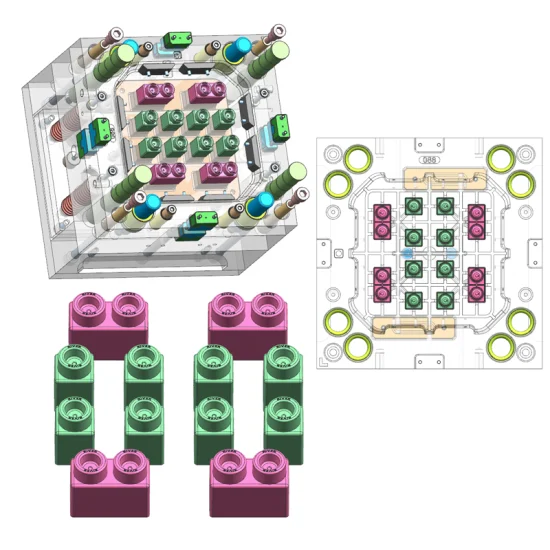

Custom Design Developing New Model Plastic Injection Molding Parts

We manufacture and export Custom Plastic Products to USA, Canada and European countries used for vary applications of In

Basic Info.

| Trademark | Exact-Plastic |

| Origin | Qingdao, China |

| HS Code | 3926909090 |

Product Description

We manufacture and export Custom Plastic Products to USA, Canada and European countries used for vary applications of Industrial, Agriculture, Auto, Electronics, Construction and Household etc.China EXACT Plastic Co., Ltd. has our own plastic injection plant, cover 3,000 square meters area. Has 20sets of plastic injection molding machines from 8ton to 800ton that can produce plastic parts from 1-8000 gram per piece.We manufacture Custom Plastic Injection Products export to USA, Canada, Germany, Denmark, Belgium, South Korea, Australia and Russia etc.The products are custom molded in new model according to the specifications in plastic injection. By the plastic material PP, PVC, PE, LDPE, HDPE, Nylon, PU, PC, PS, ABS, SBS and TPR etc. Other plastic material is also available. 99% of our products are Custom Molded according to your Drawing or Sample or Idea. Till now we have produced products used for industrial, such as various industrial equipment components; Auto & MOTO, such as internal and external accessories, lights, rear-view mirrors, handles, bumpers and other components; Construction, plastic components for house insulation system, rain store system and drainage system; Daily use, such as plastic parts of fridge, air-condition, TV set; plastic case, container and box and so on; Garden tools, such as various plastic rakes, plastic tool handles; Furniture, various plastic caps for slat bed frame; other plastic accessories for furniture. We also do various multi purpose plastic interlocking floor tiles to be used for gymnasium, garage and office. Application:

| Industrial | Furniture | Floor Tiles |

| Auto | Mining | Daily Use |

| Construction | Transport | Garden Tools |

| Furniture | Pet | Food |

Also we have our own molds plant. Our mold engineers have skill of using UG, Pro/e, SolidWorks, CAD and other 3D design software to design the molds. We have Large CNC machining centers, CNC engraving machines, EDM spark molding machines and Line cutting machines etc to produce the molds.China EXACT Plastic Co., Ltd. passed ISO9001. We also can supply products with SGS or FDA testing report.

| Manufacturing Process | Plastic Injection Molding |

| Supply | Tooling & Parts |

| Material | Polypropylene (PP), Polyethylene (PE), HDPE (High Density Polyethylene), LDPE(Low Density Polyethylene), PVC, ABS, TPR/TPE(Thermo-Plastic-Rubber TPE(Thermoplastic Elastomer), TPU (Thermoplastic Urethane), POM, Polyurethane(PU), High Impact Polystyrene (HIPS) |

| Surface Finish | Polishing, Glossy Shinny, Matt, Mirror Polishing |

| powder coating/oil painting | |

| Tolerance | +/-0.01mm or special requirements |

| Package | PE Bag, Paper carton box, plywood case/pallet/crate |

| Application | IndustrialFurnitureFloor TilesAutoMiningDaily UseConstructionTransportGarden ToolsSportsPetFood |

| Quality Control | ISO9001 |

| Drawing File Format | Solidworks, Pro/E, Auto CAD, PDF |

| Features | Customized Design |

| Sample Order Accepted | |

| Short Delivery time | |

| Competitive Prices | |

| Long time quality Insurance | |

| Professional after-sale services | |

| Inspection | PPAP |

| Delivery time | 10-15days |

| Service | Assemble and Retail Package with EAN Code |

If you want to make your plastic product, pls do feel free to contact with us now.We will supply good quality, on time service and low price.

Send to us