Multi Cavity Mould of Plastic Injection Component for Medical Device/Plastic Injection Mould Manufacturer

Basic Info.

| Model NO. | plastic injection molds & molding |

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware |

| Runner | Hot Runner |

| Design Software | AutoCAD |

| Installation | Fixed |

| Certification | TS16949, CE, ISO |

| Standard | DME |

| Customized | Customized |

| After-sales Service | Yes |

| Surface Finishing | Texture/Sandy/Mt/Ys/Spi/EDM Finish/Smooth/Glossy |

| Steel | P20, 2311, H13, 2344, Starvax 420, 236, 738h, S136 |

| Product Material | Plastic |

| Color | Customized Colors |

| Cavity Number | Single Cavity & Multi Cavity |

| Mould Base | Hasco Standard, European Standard, World Standard |

| Raw Material | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, |

| Injection Machine | 88t-1200t |

| Hot/ Cold Runner | Husky, Incoe, Yudo, Hasco, Dme, Moldmaster, Ect. |

| Mold No. | Plastic Injection Moulds |

| Tolerance | 0.02mm-0.05mm |

| Drawing Format | STP. Step. Igs. Prt. X_T |

| Transport Package | Carton Box |

| Trademark | Customised |

| Origin | China |

| HS Code | 8480410010 |

| Production Capacity | 500sets/Year |

Product Description

Product Description | OEM ODM plastic injection molding |

Plastic Materials | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

Standard | ISO9001:2008 |

Quality | RoSH and SGS standard |

Feature | Non marking and Non flash |

Size | According to your 2D, 3D Drawing |

Color,Quantity,Unit price,Tooling cost,Tooling size | To be discussed |

Package | Standard exported Wooden box packed, Fumigation process(upon required) |

Mold Building Lead Time | 20~30 working days, Part measurement report (upon required). |

Export Country | Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy...etc.: |

To be discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Stack Mold, |

Mould Base | Hasco Standard, European Standard, World Standard,DEM standard,HUSKY standard...etc |

Mould Base Material | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment |

Surface Finish | Texture(MT standard), High gloss polishing,mirror polishing |

Cavity/Core Steel | P20, 2311, H13, 2344, Starvax 420, 236, 738H, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

Mould Life | 250,000 to 1,000,000 Shots. (According to your working environment.) |

Design & Program Softwares | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

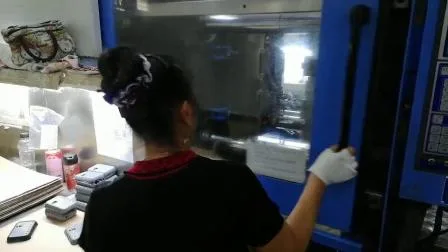

Equipments | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T |

High quality custom plastic injection moulds for automotive parts, plastic accessories

Moules d'injection plastique personnalisés de haute qualité pour les pièces automobiles et les accessoires en plastique