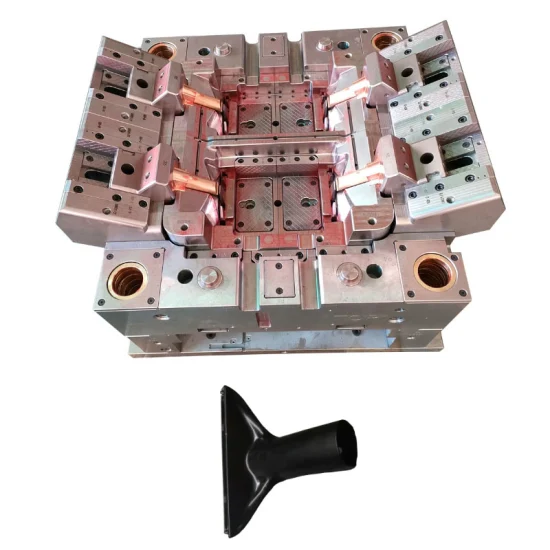

Toolmaker OEM Smooth Surface Cover Plastic Injection Mold for Dust Cleaner Machine

Basic Info.

| Model NO. | HW-1082 |

| Plastic Material | ABS |

| Application | Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | ISO, SGS |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | Any Technical Support or Service, Pls Contact Us. |

| Logistic | Air/Ocean Shipment |

| Mould Cavity&Core Material | S136 / 718h |

| Payment We Support | T/T, Paypal |

| Cooling | Water Cooling |

| 3D Design | 3-5 Days |

| Mould Life | 300,000-500,000 Shots |

| Mold Life Time | 300K~1,000K Shots |

| Ejector System | Stripper Plate,Lifter,Push Bar,Ejection Pin etc |

| Mold Materials | S45c, P20, 718, 718h, 738, 738h, Nak80, etc |

| Gate Type | Side Gate,Sub Gate,Pin Point Gate,Edge Gate etc |

| Name | Vacuum Cleaner Parts Mould |

| Transport Package | Wooden Cases/Air/Sea |

| Specification | Custom |

| Trademark | HOWE or Custom |

| Origin | Dongguan China |

| HS Code | 84107100 |

| Production Capacity | 50 Sets/Month |

Packaging & Delivery

Package Size 65.00cm * 61.00cm * 67.00cm Package Gross Weight 1100.000kgProduct Description

Mould Builder Customize Injection Molded Housing with ABS/PP/PS/POM Plastic MaterialProduct Description| Product name | Latest design molding plastic injection mould/plastic mold/plastic injection manufacturers custom service |

| Products Variety | We design and manufacture plastic injection molds auto parts, home applications, medical products, Household commodities, consumer electronics, mobile phone parts,and accessories, and many other kinds of molds in different fields. |

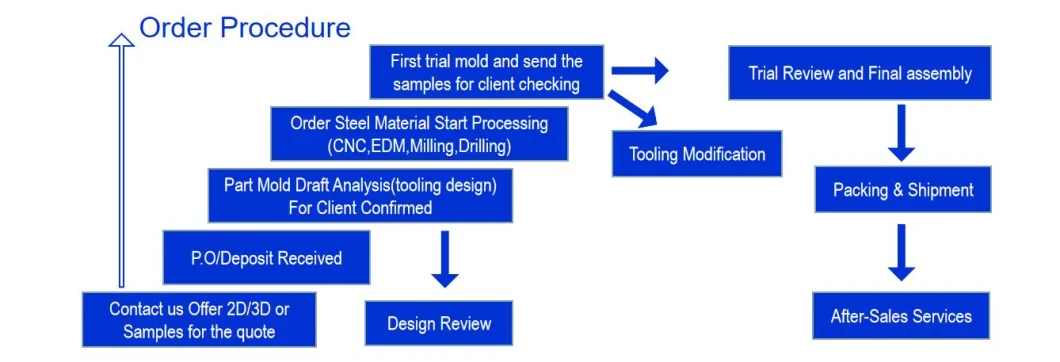

| Main services | 3D design, Prototypes, Mold design, Mold making, Mold tesing, Low volume/ High volume plastic injection production |

| Design Software | UG,Pro E Solidwork,AutoCAD,Moldflow.... |

| Core&Cavity Material | P20,H718,S136,SKD61,2738,DC53,H13.... |

| Mold base | HASCO ,DME ,LKM,JLS standard |

| Mould Cavity | Singe or multi cavity |

| Mold strandard parts | DME, HASCO, etc. |

| Runner | Hot runner, Cold runner |

| Hot Runner Brand | Yudo/ Mastip/ HASCO/ DME/ MOLD-MASTER…etc |

| Mold cold runner | Side gate,Sub gate,Pin point Gate... |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| plastic Injection Machine | 10sets,110T,140T,160T, 200T,260T,320T |

| Plastic Material | PP,Pa6,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc |

| MOQ | 1set for mold ,plastic products as per your request |

| Mold Life | 300000-500000 shots as per customers' requirement |

| Inspection | As customers' requirements |

| Delivery | Air cargo, Sea shipping |

| Lead time | 25-35days for mold,plastic products according to quantity |

Howe is a company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and have been engagaed in the manufacturing sector since our inception. Is an OEM/ODM factory, customized your products to meet your needs is our advantage. We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed and excellent designers will ensure that your imagination is incorporated into the actual product. If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!

How to reach our company Dongguan?

1.From Shenzhen by bus 1 hour.

2.From Guangzhou by bus 1.5 hours.

3.From Shanghai by air 2 hours.

Welcome To Visit Our Company and Inquiry Us! Customer Demand is Our ongoing motivation!

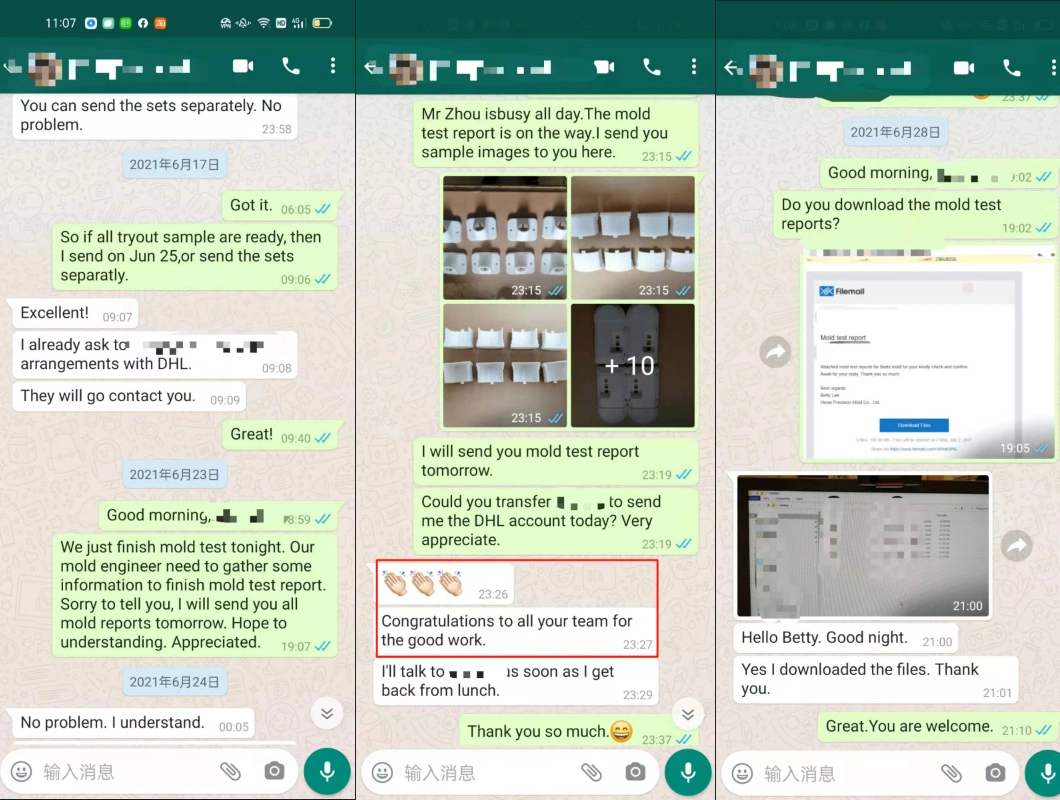

Customer Feedback

Custom Plastic Injection Molding Applications:

1. Plastic injection molding parts for architectural parts

2. Plastic injection molded auto components

3. Injection-molded household utility products

4. Plastic molded electronic enclosures

5. Plastic molds for medical & dental products

6. Injection molding parts for model shops, toys

7. Injection plastic parts for new product design & development

8. Custom plastic parts for construction

9. Injection plastic parts for others like cosmetic case

10. Plastic injection for Information Technology

11. Molded plastic parts for payment system

12. Precision plastic parts for Agricultural equipment

1.What is your business?

1) Precision Plastic Mold manufacture

2) Medium and large plastic mold manufacture

Mold payment terms:40%-30%-30%.The first payment is when you sign the order, you should pay us 40% of the total value; the second payment is when you receive our sample product, you should pay us 30% of the total value; the last payment is when we deliver the mold for you, you should pay off the balance payment,30% of the total value.

2. How about your part payment terms?

Part payment terms:50%-50%.The first payment is when you sign the order, you should pay us 50% of the total value to purchase the material; The last payment is when we deliver the part for you, you should pay off the balance payment,50% of the total value.

3. What's your lead time?

For most mould, 15-45 working days ( not including Chinese official holidays ) after deposit received and mould drawings approved.

4.What type of process do you use on mould surface?

1) Mirror polish

2)Texture

3) Plating treatment on the core and cavity.

4) According to the customers' products need.

5. How to approval samples?

1) You can come to have the mould test directly.

2) We could send samples & mould running video to you.

6.What's your after-sales?

After-sales: Our customer's mold drawings and the whole data will be kept in a database for 5 years at least.So that when you need our technical support or service, we can be easy and possible to serve you and your customers.